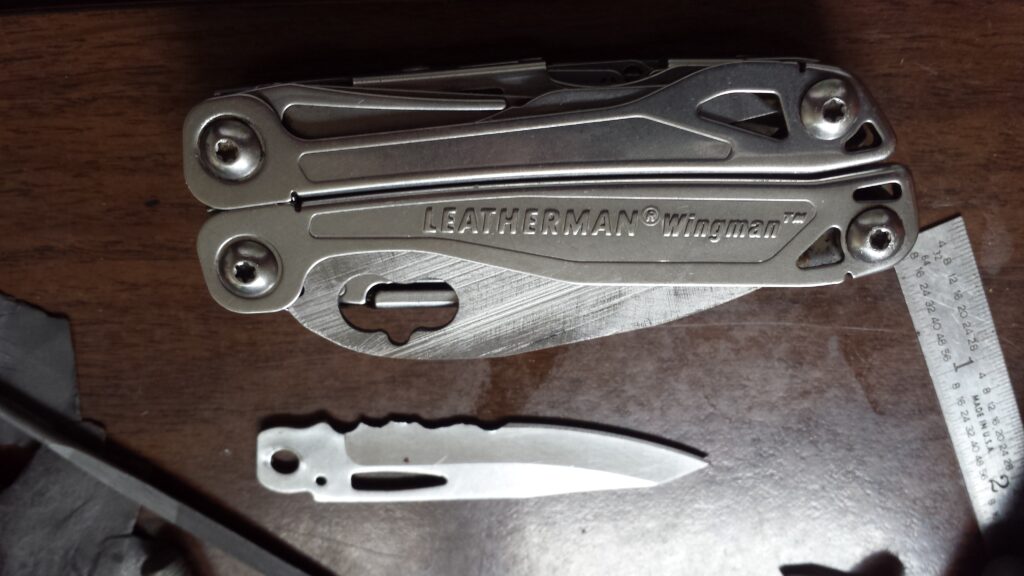

I use a Leatherman Wingman all the time. I think I paid $20 for it, which means it’s cheap enough (made in China of course) that I don’t care if I break it. The one aspect I really don’t like is the (supposedly) 420a Stainless Knife blade. It doesn’t hold an edge at all, and is frankly almost useless sometimes.

So I grabbed some A2 scrap tool steel and started grinding away to make a newer knife blade. A2 isn’t the typical knife steel, but it’s tough, fairly easy to heat treat (the A stands for air quenching) and it’s got to be better than the “420” steel of the wingman.